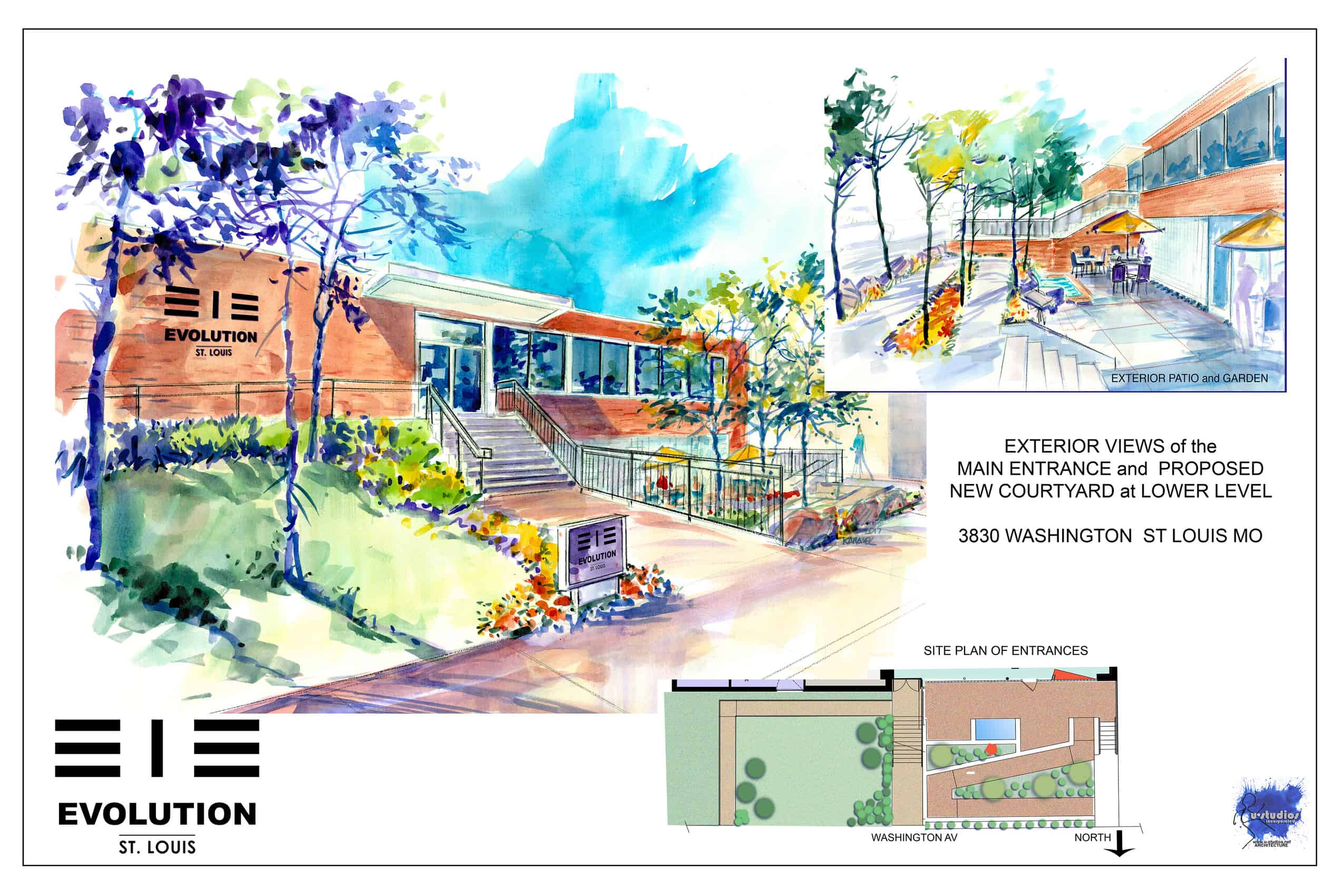

On Thursday, Gary Wassner attended the ribbon-cutting ceremony for Evolution St. Louis, a new high-tech knit-manufacturing facility in downtown St. Louis, Missouri. Why St. Louis? Well, according to Wassner there really was no other choice.

“The thing we’re really missing in this country right now is manufacturing,” Wassner said. “I tried in New York, but we couldn’t get the city’s support. The rent is too high, labor is too [expensive], the tax situation, everything was working against us.”

St. Louis, on the other hand, welcomed Wassner and his business partners, Jon Lewis and John Elmuccio, with open arms. “The city has been so cooperative,” he said. “They have an ample labor pool and a ton of great, vacant real estate. Everyone here has been so enthusiastic. In my whole career this has been the most painless creation process I’ve ever been involved with.”

- Evolution St. Louis

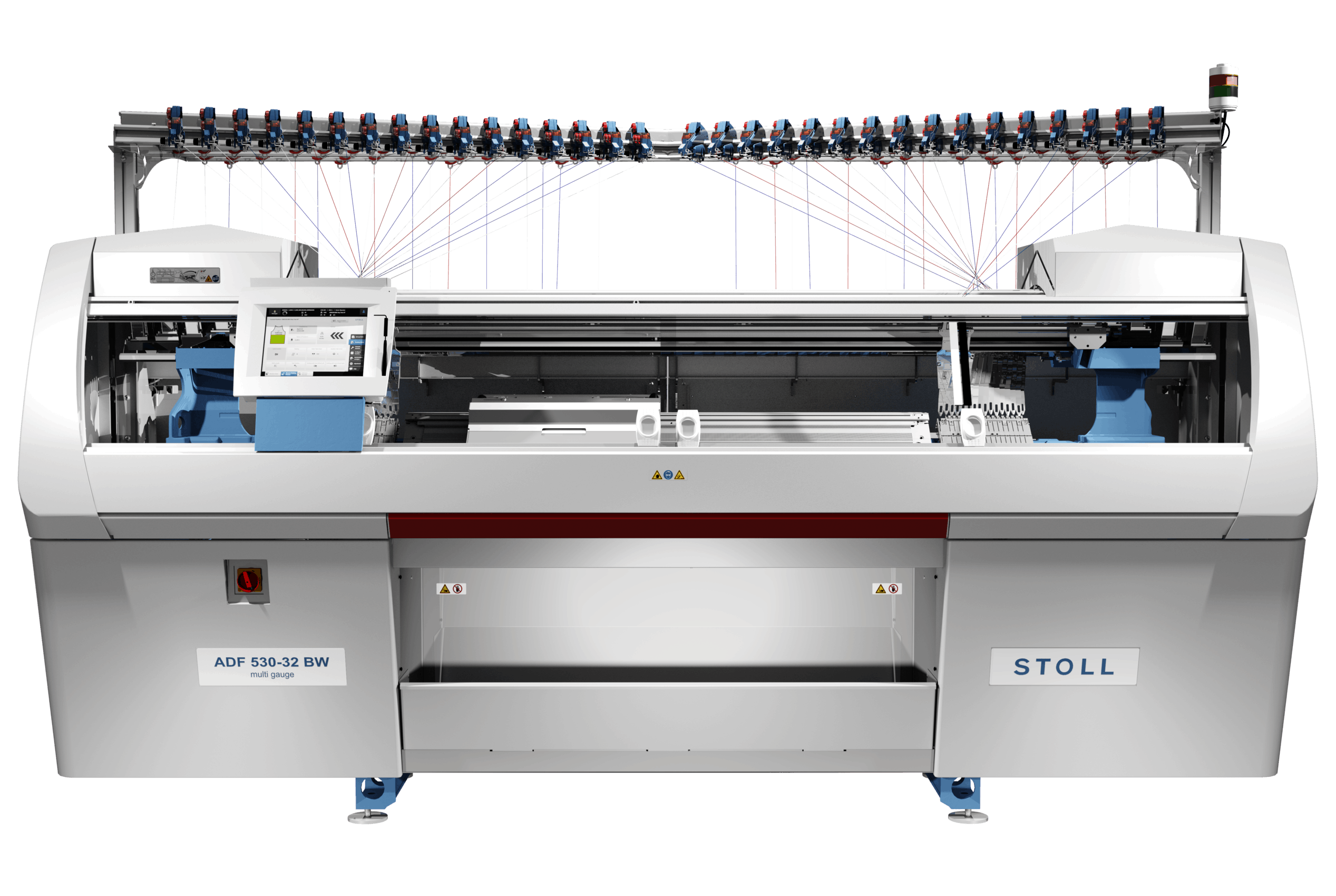

The new factory will offer contemporary and luxury apparel companies a competitively-priced, domestic alternative to Asian knitwear manufacturing. Utilizing the most advanced knitting machines available, Evolution St. Louis says they can bring garments to market 65 percent faster than their oversees competitors, without the need to impose high manufacturing minimums. It’s a definite boon to boutique and direct-to-consumer businesses, for whom adaptability is essential to their success. “A lot of my clients are mid-size brands who do a lot of business with specialty stores like Intermix or Barneys,” said Wassner. “They need to be able to reorder a couple hundred units of a single style, but to do that in China is impossible, so they have to gamble on inventory and hope that the style they ordered extra of is the style that stores want.”

“Now designers can react to demand, rather than trying to forecast demand,” says Lewis.

- One of Evolution St. Louis’ new STOLL knitting machines

Another advantage of domestic manufacturing is the protection it gives businesses from rising tariffs on products coming from oversees, especially from China. Wages are much higher in the US, but the efficiency of the new knitting machines means that a single technician can now manage 12 machines at once, dramatically reducing Evolution St. Louis’ operating costs. Even so, the company expects to create 50 to 60 new jobs within its first three years, with more to follow as they grow.

Wassner, his partners, and the city of St. Louis hope this new factory will help jumpstart the once-thriving St. Louis garment industry. “We once had a garment district that was second [in America] only to New York,” said Susan Sherman, co-founder of the St. Louis Fashion Fund and the woman responsible for bringing Wassner and the city together. “We have the bones. People here get it and we are a city that needs this. We need a new Industry.”

- Evolution St. Louis

- Evolution St. Louis

The Fashion Fund Sherman runs is dedicated to nurturing young, up-and-coming designers and revitalizing the city’s garment district. She first met Wassner when he came to St. Louis to judge an emerging designers competition and the two have kept in touch and worked together ever since, with Wassner returning to the city periodically to mentor and speak at key events.

Wassner and Sherman are hoping that Evolution St. Louis will entice young designers to the area to build their own businesses. “We have a young designer community here,” said Sherman, “emerging designers who maybe can’t afford New York or LA or Nashville. What we’re hoping is to bring even more young designers here to utilize this innovation and populate the old garment district buildings.”

“And we’re working on the ability to subsidize some of these young designers, if they move here, and help get them started,” added Wassner.

As the project scales, Wassner hopes to bring more large-scale manufacturing back to the area.”Eventually, [Evolution St. Louis] will be able to inventory undyed yarns and turn things around even faster,” he said. “Until the mills come back, there’s no way to manufacture yarn here now, But once that happens, there’s no reason we couldn’t have a yarn factory right next to this factory to create even more synergy and create these products even more quickly.”

Subscribe to our newsletter and follow us on Facebook and Instagram to stay up to date on all the latest fashion news and juicy industry gossip.