It is easy to forget just how much time and effort goes into creating the clothes you see on the runway, especially in a world where Zara seems capable of knocking off looks faster than you can double-tap an Instagram. But any true fashion aficionado knows that there is a big difference between a runway piece from, say, Dior, and the pale imitation that all-too-quickly makes its way into a fast-fashion retailer near you.

Take this jumpsuit for example. It probably spent all of two minutes on the runway, but the thing took a team of busy little Dior worker bees days to complete. Let’s break it down, shall we?

Dior spring 2018 (FirstVIEW)

24 — That’s the number of hours it took to design and finalize the look, according to Dior.

Designer Maria Grazia Chiuri is very particular!

(Dior)

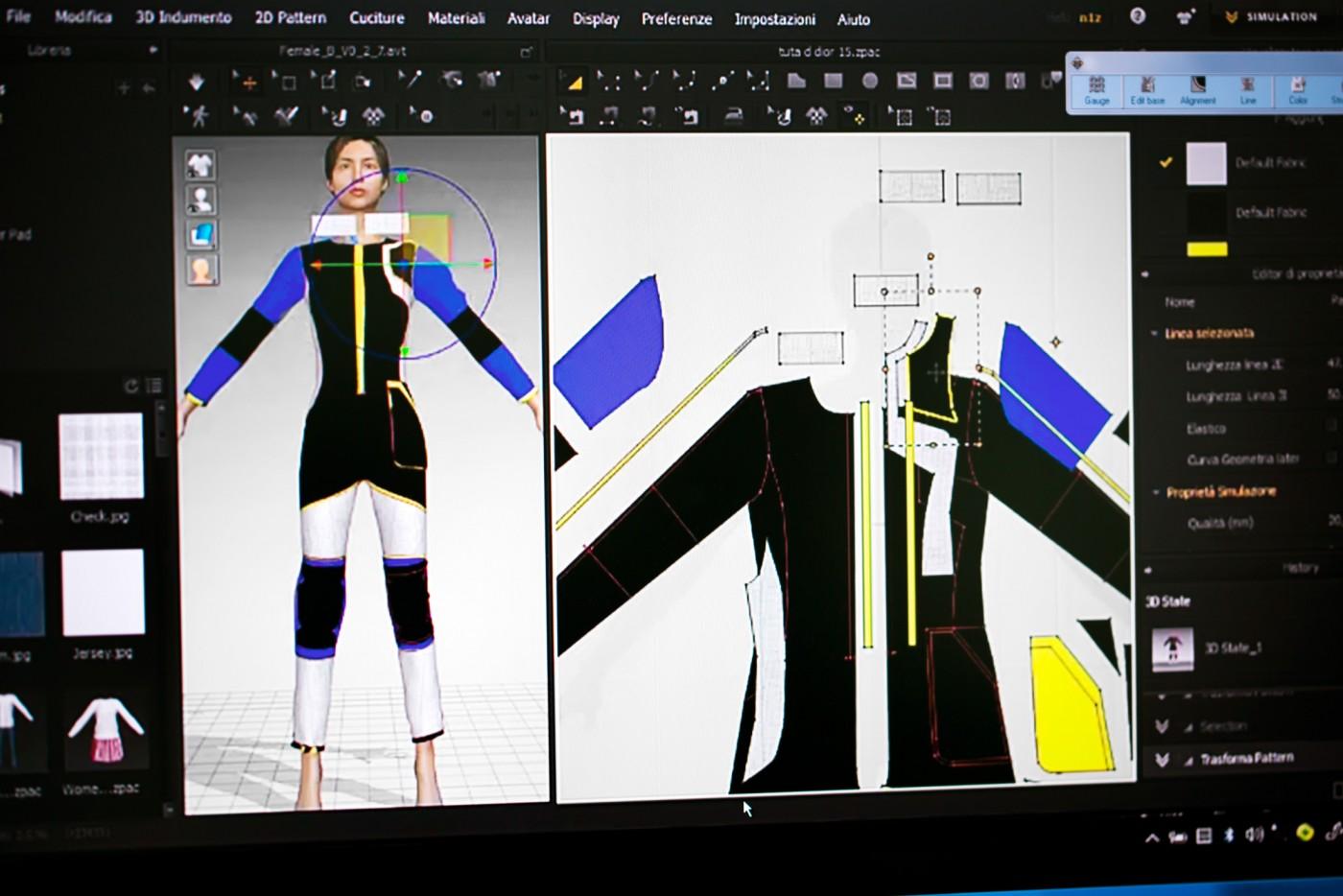

10 — That’s how how many days it took just to figure out how to make it.

Sometimes, the things that look the simplest are actually the most complex. The design program for this particular piece was formulated entirely from scratch by experienced artisans using the best computer design software available and it still took them two weeks to figure it all out.

(Dior)

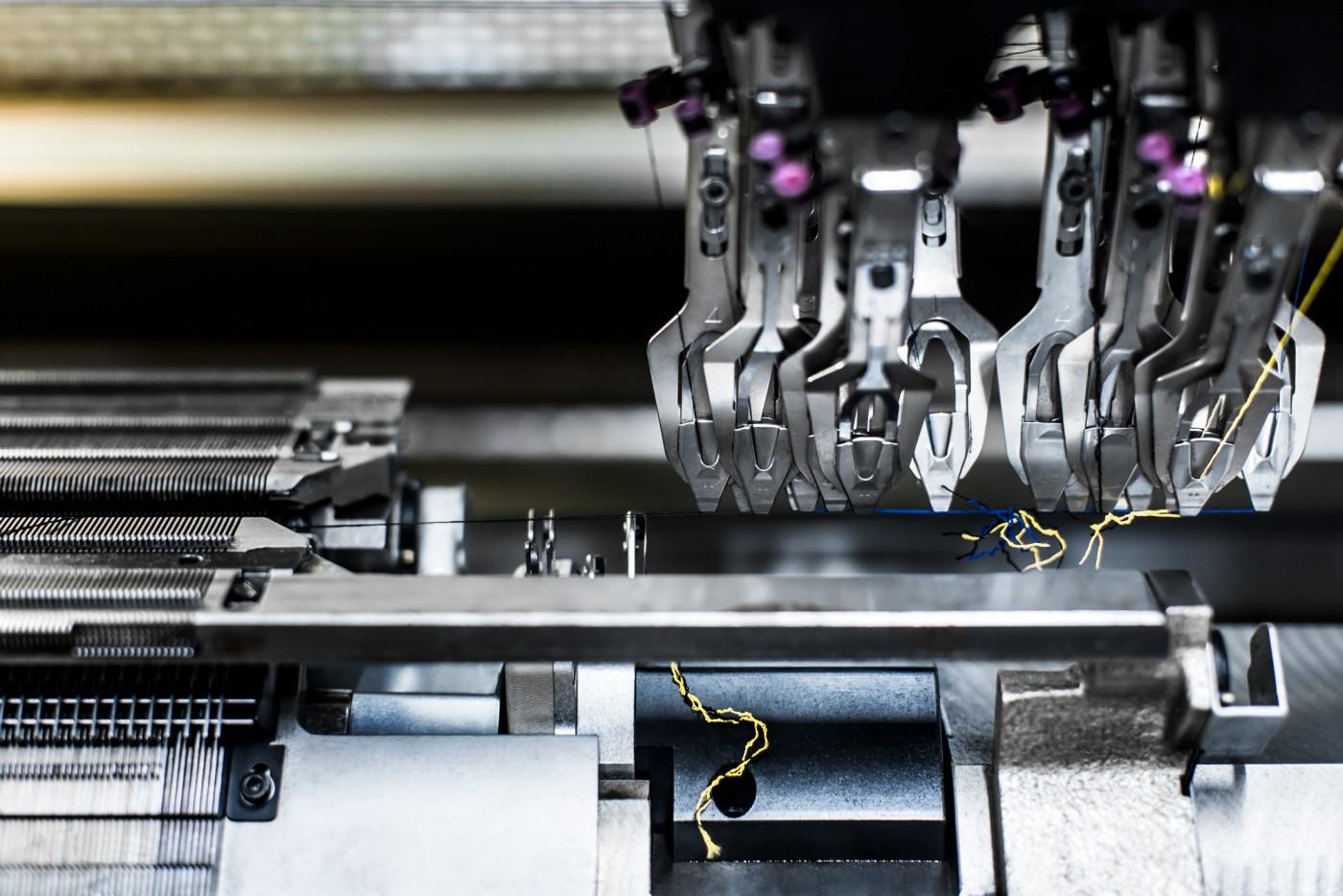

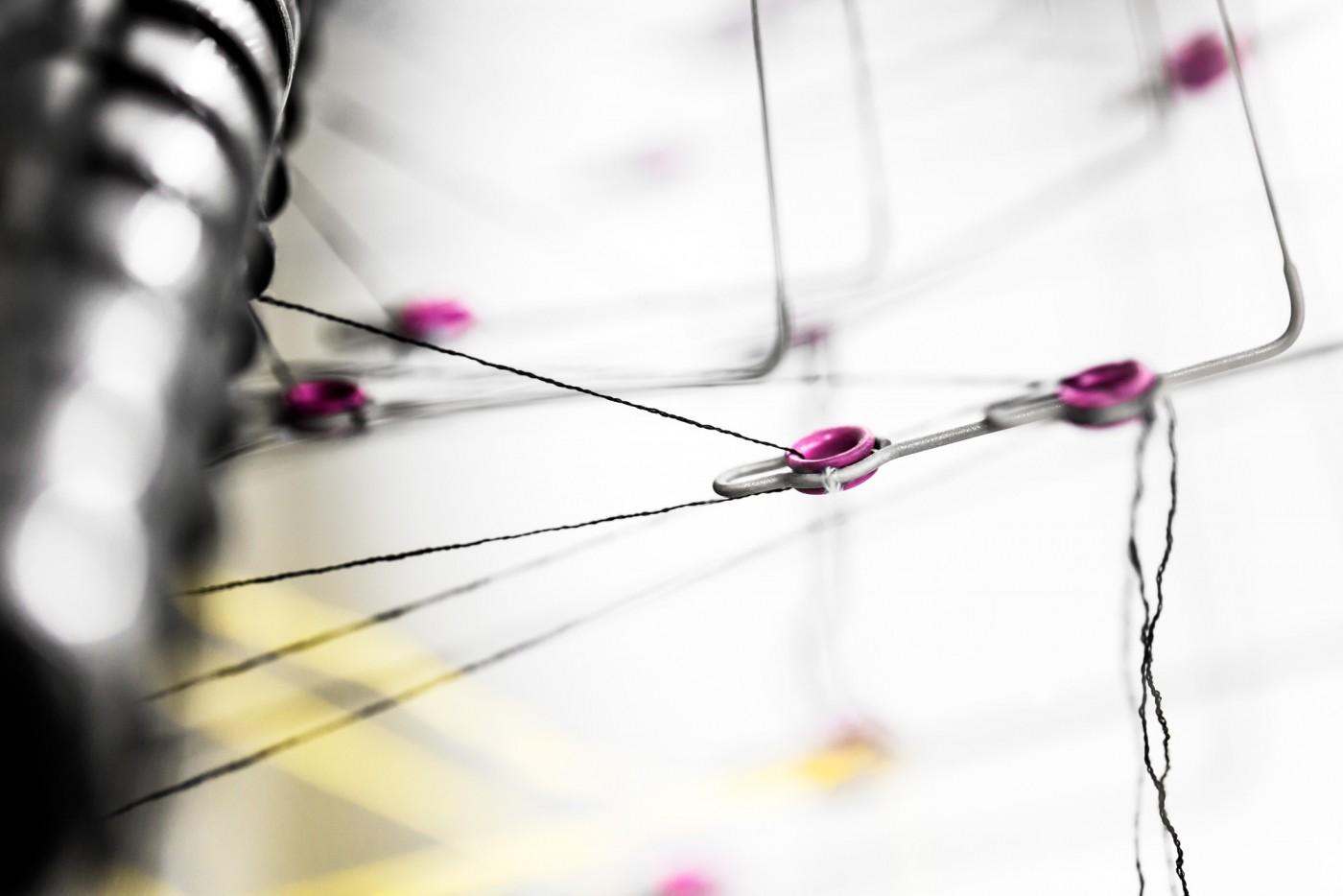

9 — That’s the number of hours it took the machines to knit the dozens of individual panels that make up the jumpsuit.

The garment is made with viscose thread, knit at an 18-gauge fineness. That means 18 loops per inch. That’s tiny — way smaller than a human could ever knit by hand. Not without going insane and losing their eyesight in the process, at least.

(Dior)

(Dior)

0 — That’s the number of seams it has.

Part of what makes this particular jumpsuit so special is that it is all one piece — no cuts, no seams. The color blocking is the result of an intarsia knitting technique, which means every panel, even those narrow yellow ones that make up the lines around the pockets, is knit individually and then joined by hand to create a seamless garment that simply cannot be replicated by a machine alone.

(Dior)

5 — That’s how many people worked on it.

This includes two artisans who specialize in the making of single-piece garments because, at this level of craftsmanship, that kind of specialization is required.

(Dior)

1 — That’s how many chances they had to get it right.

Usually, a designer would use machines to produce a toile version of a garment in advance so they could work out any design issues before rendering the piece in its final form with more expensive materials and finishings. However, in the case of this jumpsuit, the nature of its design and manufacture meant that the team working on it couldn’t do a practice run with a toile. They just had to go for it right off the bat. Can you say PRESSURE?!

(Dior)

Ironically, the one number I don’t have here is the price. It is available upon request in any of Dior’s boutiques, though.

Check out more process pics below and make sure to watch the video at the top of this post to see the whole shebang in action. Honestly, it’s kind of mesmerizing.

- (Dior)

- (Dior)

- (Dior)

- (Dior)

- (Dior)

- (Dior)

- (Dior)

- (Dior)

- (Dior)

Subscribe to our newsletter and follow us on Facebook to stay up to date on all the latest fashion news and juicy industry gossip.